The horticultural industry is rapidly evolving with the integration of innovative technologies. One such breakthrough is the development of automated shade net manufacturing systems, designed to improve efficiency and productivity. These advanced systems harness computer-controlled machinery and software to precisely manufacture shade nets of diverse sizes and structures, catering to the individual needs of growers. By automating the manufacturing process, these systems decrease manual labor, errors, and manufacturing duration. This achieves a greater output of superior shade nets at reduced cost.

- Advantages of automated shade net manufacturing systems include:

- Optimized output

- Precise fabrication

- Reduced overhead

- Customization options

Cutting-Edge High-Performance Agro Shade Net Production Line

Our state-of-the-art High-Performance Agro Shade Net Production Line is designed to maximizing efficiency and output. This robust system incorporates streamlined processes from raw material processing to the final, high-quality shade net product. The line utilizes {advanced{ control systems for precise fabric cutting, ensuring uniform product dimensions and quality.

- Furthermore, our production line incorporates sustainable practices, minimizing waste and reducing its environmental footprint.

- Consequently, we provide durable and efficient shade nets that fulfill the diverse needs of farmers and agricultural operations.

High-Performance Shade Net Making Machine for Agriculture

For growers looking to enhance crop yield and reduce the harmful effects of scorching sun, an efficient shade net making machine is an vital investment. These machines simplify the entire process of producing high-quality shade nets, from fabricating the netting to cutting the edges. With increased output, farmers can manufacture shade nets in a prompt manner, ensuring their crops are always shielded from the sun's strength. A well-designed machine incorporates durable materials and cutting-edge technology to provide long-lasting performance and reliable results. By embracing this efficient shade net making machine, farmers can substantially improve their agricultural practices.

Heavy Duty Shade Net Manufacturing Machinery

Fabricating shade nets on an industrial scale necessitates specialized machinery. This array of devices is designed to effectively manufacture large quantities of shade net fabric. Key pieces often include automatic cutting systems, high-speed stitching machines, and sturdy frames for handling heavy rolls of fabric. These state-of-the-art fabrication systems enable manufacturers to create high-quality shade nets in a efficient and economical manner.

Additionally, industrial grade shade net fabricating equipment often features safety systems to mitigate the risk of operator injury. This emphasis to safety is crucial in a manufacturing environment where heavy check here machinery and sharp tools are routinely used.

Robust Shade Net Loom for Large-Scale Production

Large-scale manufacturing of shade nets requires a reliable and strong loom. A well-designed loom can significantly improve efficiency, lower production costs, and ensure consistent uniformity in the final product. Selecting a loom made from superior materials is essential for withstanding the demands of continuous operation.

- Characteristics to consider when choosing a shade net loom include its weaving capacity, yarn gauge compatibility, and ease of servicing.

- Automation features like automatic tensioning and thread release can further enhance productivity.

- Furthermore, a user-friendly design with intuitive controls makes operation more efficient and accessible to a wider range of workers.

Investing in a trustworthy shade net loom is a crucial step for businesses aiming to achieve high-volume production while maintaining product specifications.

High-Accuracy Shade Net Weaving Machine

The advanced Precision Shade Net Weaving Machine is a revolutionary device designed to create shade nets with exceptional accuracy. This machine utilizes sophisticated technology to interlace the net threads with {remarkableconsistency. The result is a shade net that is both durable and efficient, providing optimal heat protection for various uses.

- Additionally, the machine's versatility allows it to produce shade nets of multiple sizes and densities to fulfill specific customer requirements.

- Consequently, the Precision Shade Net Weaving Machine is an essential asset for enterprises involved in agriculture, horticulture, and other fields that demand high-quality shade nets.

Miniature Shade Net Making Machine for Tiny Farms

Farming on a limited scale often presents unique obstacles. One such challenge is providing adequate shade with crops, especially in areas with intense sunlight. Nevertheless, compact shade net making machines are now available to aid small farmers toward overcoming this issue. These machines are designed to be affordable, easy to operate, and capable of producing durable shade nets that can effectively safeguard crops from harmful UV rays.

- This machines typically consist of a base with rotating rollers that pull shade net material along a series of clips.

- These can often be equipped with features like automatic stretching mechanisms and built-in cutting systems, further boosting their productivity.

- Additionally, compact shade net making machines commonly run on electricity or gasoline, allowing them appropriate for use in a wide range of locations.

Acquiring in a compact shade net making machine can be a beneficial investment with small farmers. It lowers reliance on outsourced shade nets, saving costs in the long run.

Bespoke Shade Net Manufacturing

When demanding shade net solutions that are precisely suited to your specific needs, look no further than our adaptable fabrication choices. Our team of skilled fabricators leverages the most current equipment to manufacture shade nets of diverse extent and configuration. We offer a broad variety of textures to guarantee optimal heat protection, while fulfilling your decorative preferences.

- Optimize your outdoor comfort

- Shield your crops from harmful sunlight

- Create a shaded area for leisure

Innovative Shade Net Manufacturing Technology

The shade net manufacturing industry is rapidly progressing with the adoption of cutting-edge technologies. These advancements are fueling significant enhancements in shade net production, resulting products that are more durable, efficient, and sustainable. Computerization plays a essential role in modern shade net manufacturing, streamlining processes such as weaving, cutting, and stitching.

- Advanced design software allows manufacturers to create precise patterns and optimize shade net performance based on specific applications.

- Automated material handling systems guarantee smooth and efficient movement of materials throughout the production process.

- Detailed cutting technologies reduce waste and generate shade nets with exceptional accuracy.

Moreover, the combination of renewable energy sources, such as solar power, is becoming increasingly prevalent in shade net manufacturing facilities. This commitment to sustainability not only reduces the environmental impact but also aids a more sustainable production process.

Automated Shade Net Tying and Finishing System

In the realm of agricultural advancement, a revolutionary system/technology/solution has emerged to streamline shade net installation. This automated/automatic/mechanized Shade Net Tying and Finishing System/Apparatus/Unit significantly/drastically/substantially enhances efficiency by automating the tedious process of tying and finishing shade nets. The system/mechanism/device effectively secures/fastens/attaches shade net panels to supporting structures, eliminating/reducing/minimizing manual labor and human error. Its precise/accurate/refined operation ensures a strong/durable/robust and long-lasting/sustainable/reliable installation, enhancing/optimizing/maximizing the lifespan of shade nets.

- Benefits/Advantages/Features

- Increased efficiency/Reduced labor costs/Enhanced productivity

- Improved net security/Stronger installations/Durable connections

High-Speed Shade Net Extrusion and Weaving

Shade net manufacturing necessitates high-speed extrusion and weaving processes. These processes provide the manufacture of durable and efficient shade nets for a diverse range of applications.

Extrusion utilizes melting plastic materials and forcing them through dies to create the desired shape and size of the shade net strands. Subsequently, these filaments are woven together using high-speed looms to form the final shade net fabric.

This process enables for the creation of shade nets in large quantities, meeting the growing need for this essential agricultural and horticultural product. Optimizing extrusion and weaving speeds contributes to increased efficiency and lowered production costs.

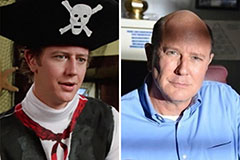

Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!